Simplifying the Science of Shielding.

Thank you for visiting our site.

If you're considering to install an MRI machine, you will need Electromagnetic Shielding. Where you will need our expertise. And if you're exploring CT, PET, or Nuclear Medicine, we’re here to simplify your requirements and deliver clear, tailored solutions—without the confusion or the fuss.

We specialise in the design of both electromagnetic and ionising radiation shielding. Decades of combined expertise from our team brings deep technical knowledge and a genuine pride in our professional approach. This pride drives us to continually refine and improve our methods.

In a time when scientific and technical education is too often overlooked, we’re also committed to mentoring the next generation—encouraging practical thinking, common sense, and a hands-on approach to every challenge.

Simple. Precise. Professional.

That's how we work — and how we make you look good.

- ISO 9001:2015 Certified Quality Management

- Custom Solutions for Unique Requirements

- Worldwide Distribution Network

What We Stand For

Whether you're building in-house or thinking outside the box, we create tailored environments for MRI, CT, PET, and Nuclear Medicine—with equal dedication to Radiology and Radiotherapy. We are proudly connected to some of the most respected organisations across Australasia, Japan, Europe, and the USA. Our reach also extends to China, a region rapidly advancing and demonstrating impressive expertise and innovation in recent years.

Purpose-Built Shielding

We specialise in shielding solutions for MRI, CT, PET, Nuclear Medicine, and more—delivering precision, compliance, and peace of mind. Whether electromagnetic or ionising, our shielding reduces exposure for dedicated personnel and ensures safe, seamless treatment environments.

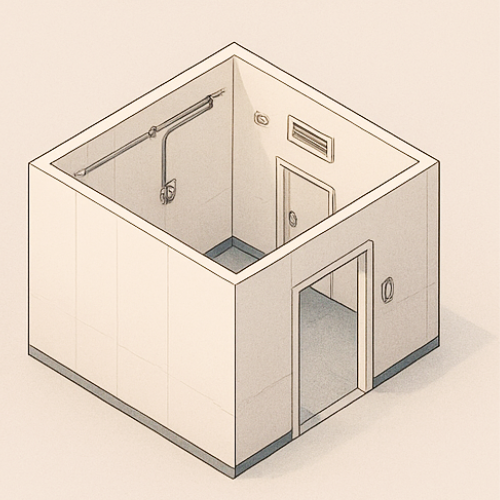

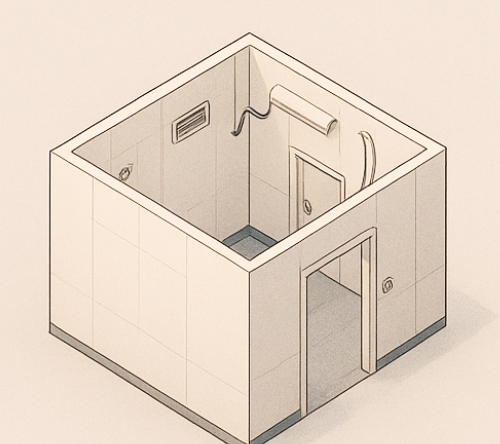

Modular Imaging Suites

Our pre-fabricated Electromagentic shieling solutions are deployed rapidly to avoid downtime. Beyond construction, our experts provide certification, training, and guidance on electromagnetic radiation—supporting your growth every step of the way.

Regulation, Simplified

We know AUS and NZ regulations inside out, handling all documentation with ease. Our job isn’t done until your facility is fully operational. No space? We offer prefabricated suites—installed anywhere with minimal disruption to your workflow.

Reputation by Referral

Our name is mentioned only by the best—because we’ve earned it. Trusted by leading equipment suppliers, we’ve built rock-solid partnerships through consistent delivery and deep expertise. When performance matters, we’re the team they call.

Complete Shielding Solutions

From initial planning to final testing, we provide comprehensive Faraday cage installation and shielding services for all types of medical imaging facilities.

Electromagnetic Shielding for MRI

Complete radiofrequency shielding using copper-aluminium mesh with sound cancelation, protecting staff operating in these facilities and help patients to get a more accurate image.

Learn MorePET & CT

Designing and providing calculations for P.E.T and CT with Gamma and X-ray radiation, is a shielding of corcern by local and international authoroties. As this is not only based on sound and electromagnetic field but deep penetration of Gamma Rays that can damage DNA and critical organs in the human body.

Learn MoreX-ray

The energy to applied to digital X-ray in the States is much less than it was 30 years ago. So, in this area, there is a more relaxed approach but it is still of corcern to local and International authoroties regarding the doses of radiation given to patients and operators in these facilities. Neither an over or underdose is good for patients, so annual calibrations of this equipment is required.

Learn MoreRadiation Therapy

Being the area of medicine utilising the highest levels of Radioactivity, several regulations and testing is required to make sure that this facility will provide a therapy service to patients without exposing personnel. A number of calculations are required to achieve maximum safety in applying the ALARA principle.

Learn MoreDay Surgery

Preparations of the facility can also be addressed for general surgery or laser surgery.

Learn MoreMRI Electromagnetic Shielding Installation Process

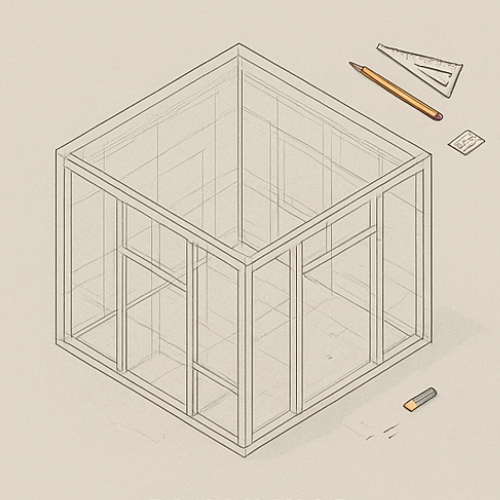

Follow our comprehensive 5-stage installation process that transforms your space into a fully compliant MRI suite. From initial preparation to final certification, every step is executed with precision and expertise.

Site Preparation & Planning

Our expert team conducts comprehensive site assessment and preparation, ensuring optimal conditions for Faraday cage installation. This critical first step sets the foundation for a successful project.

- Detailed site survey and measurements

- Structural assessment and load calculations

- Electrical and mechanical services planning

- Compliance documentation preparation

Key Specifications

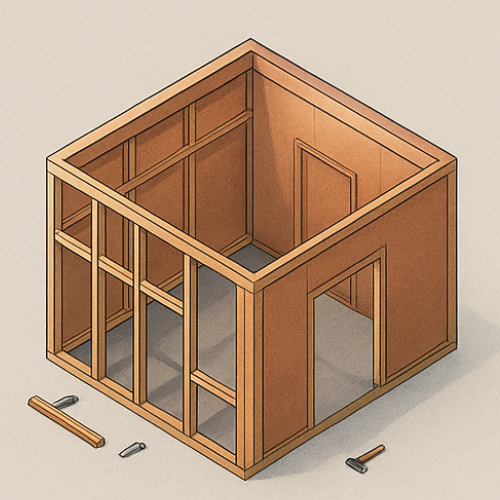

Framework Installation

Precision installation of the structural framework that will support the Faraday shielding. Our engineered approach ensures perfect alignment and structural integrity for long-term performance.

- Steel framework construction

- Penetration panel mounting

- Structural reinforcement installation

- Quality control measurements

Technical Details

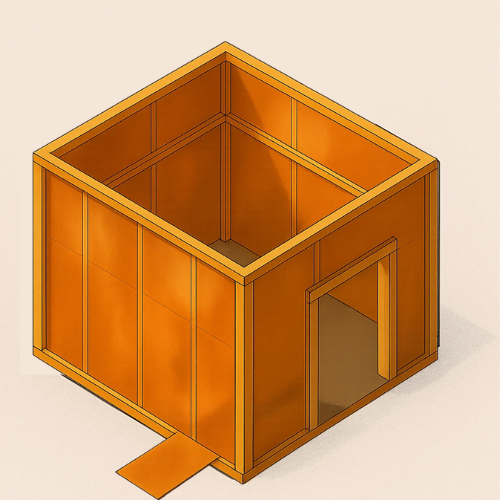

RF Shielding Installation

Installation of high-grade copper mesh RF shielding with precision welding and seamless joints. This critical stage creates the electromagnetic barrier essential for MRI operation.

- Copper mesh application

- Precision welding of joints

- Penetration panel integration

- Continuity testing

Shielding Specifications

Surface Finishing

Professional surface finishing with specialized materials that maintain shielding integrity while providing a clean, medical-grade appearance suitable for patient environments.

- Specialized primer application

- Medical-grade paint finishing

- Surface smoothing and preparation

- Clean room protocols

Finishing Standards

Testing & Certification

Comprehensive testing and certification of the completed Faraday cage installation. Our rigorous quality assurance ensures full compliance with international standards and optimal performance.

- RF attenuation testing

- Magnetic field measurements

- Safety compliance verification

- Final certification documentation

Certification Standards

Ready to Secure Your MRI Facility?

Get expert consultation and a detailed quote for your shielding project. Our team is ready to help you create a safe, compliant imaging environment.

Schedule Consultation